Leading Manufacturer for Automatic Bagging Machine - Flowmeter Filling Machine|Compliant With CGMP Standards – Yilong Detail:

Product description

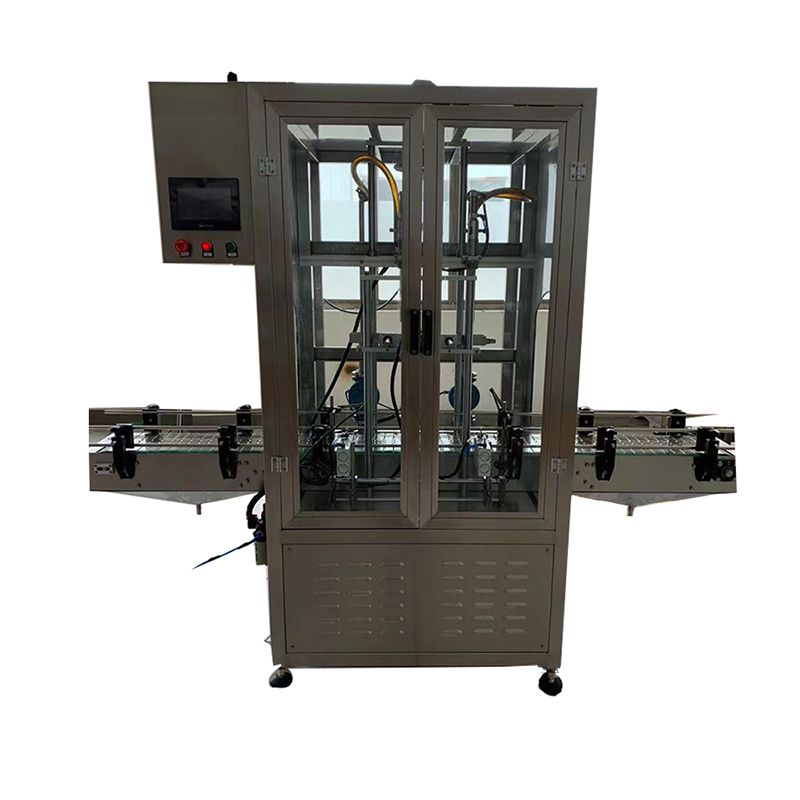

This machine is a new generation of quantitative filling equipment developed by our company by introducing and absorbing advanced European technology. 5-30

The liter flowmeter filling production line adopts advanced flowmeter to control the measurement, and the filling accuracy is two thousandths, which is suitable for filling all kinds of edible oils. The degree of automation of operation is high, the filling amount can be adjusted at will on the man-machine interface, and the operation is simple and clear. , by controlling

Filling parameters to achieve different metering. Linear bottle feeding and positioning makes it easier to change containers and change filling volume adjustment

Simple, quantitative filling of different containers can be achieved by replacing a few accessories. Electrical and pneumatic components use world-renowned brands,

The control system adopts Japan’s Mitsubishi PLC programmable controller with man-machine interface, with novel design and beautiful appearance. has self

High degree of automation, stable and reliable performance, high filling accuracy, strong applicability, simple and convenient operation and adjustment, etc. widely

It is suitable for filling of low-viscosity fluids such as various mineral water, purified water, edible oil, lubricating oil and liquid medicine. Replace anti-corrosion

The pump head and flowmeter can complete the quantitative filling of corrosive liquids.

Technical parameters

| Applicable specifications | 5-30L |

| Production capacity | 5L 10-12 bottles/min (depending on the bottle specifications and filling volume) |

| Air consumption | 15m3/h Air pressure, 0.3-0.4Kg/cm2 |

| Power | 1.5kw |

| Weight | 600kg |

| Dimensions | 2000×1200×1800mm |

control system

The quality of the machine fully complies with EU and CGMP standards. Our company adopts advanced PLC program control, medium

Text interface touch screen display, PLC program control and touch screen operation procedures are as follows: manual adjustment program, automatic

Control program, parameter setting program.

Main configuration

| Serial number | Name | Manufacturer |

| 1 | PLC | Mitsubishi |

| 2 | Inverter | Mitsubishi |

| 3 | Touch screen | Taiwan Weilun |

| 4 | Plastic pump | Domestic |

| 5 | Flowmeter | Domestic |

| 6 | Low voltage electrical appliances | Schneider |

| 7 | Main material | 304 stainless steel |

| 8 | The electromagnetic valve | AirTAC |

| 9 | Cylinder | AirTAC |

Product detail pictures:

Related Product Guide:

We often persist with the theory "Quality To start with, Prestige Supreme". We are fully committed to delivering our clientele with competitively priced good quality items, prompt delivery and experienced support for Leading Manufacturer for Automatic Bagging Machine - Flowmeter Filling Machine|Compliant With CGMP Standards – Yilong , The product will supply to all over the world, such as: Provence, Nepal, Nicaragua, Profession, Devoting are always fundamental to our mission. We've got always been in line with serving customers, creating value management objectives and adhering to the sincerity, dedication, persistent management idea.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!