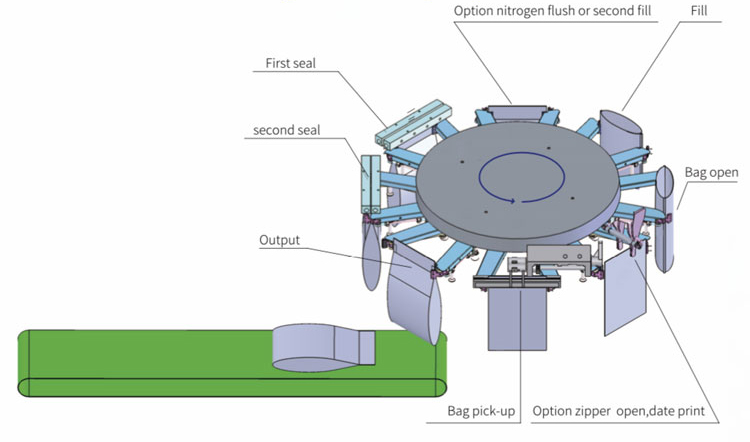

1.Bag Feeding

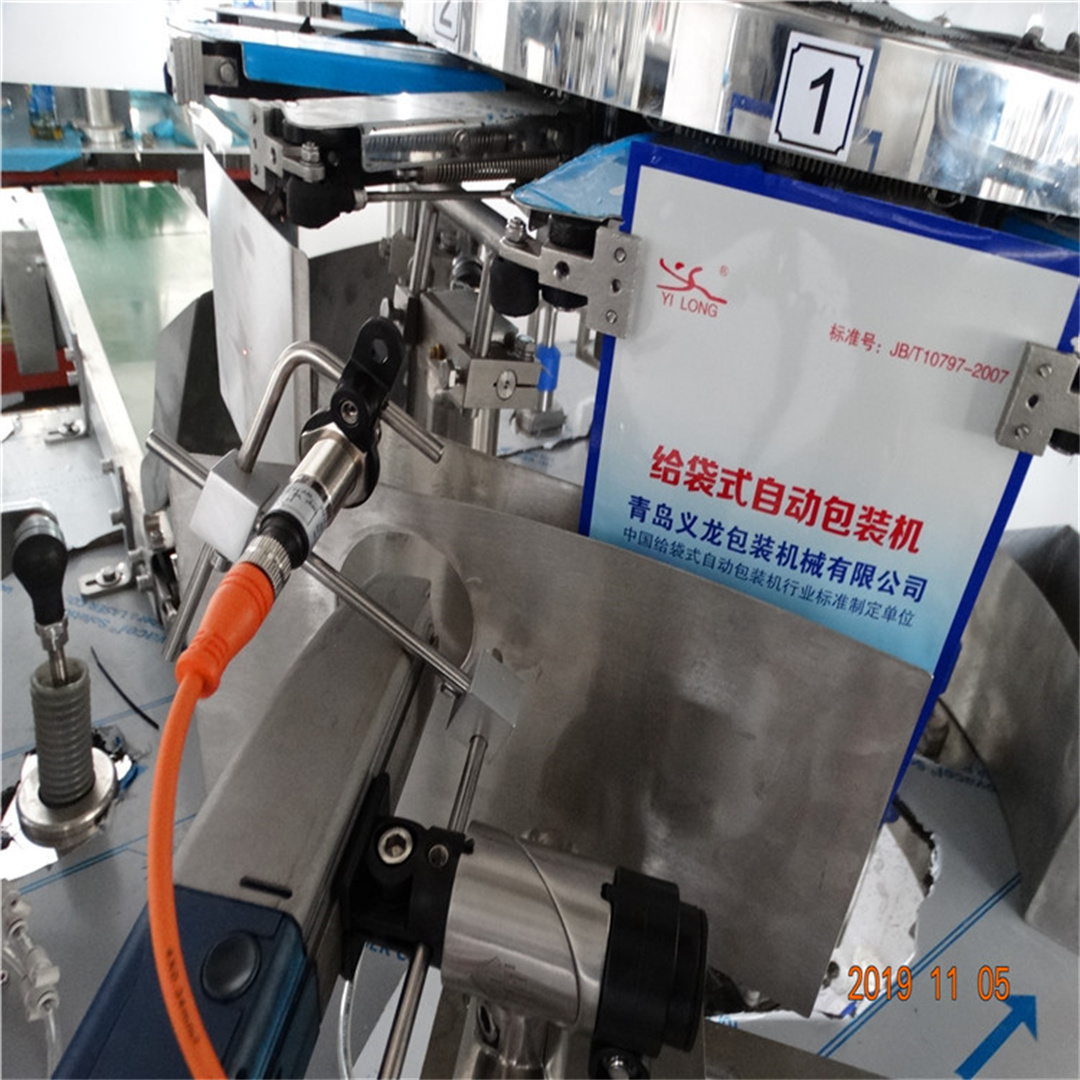

2.Optional Zipper open and Date print

3.Bag mouth and bottom open

4. Product fill

5.Option: Solid :Nitrogen charge,Powder:Bag mouth clean,

Liquid:Secondary filling

6.Heat sealing

7.Heat sealing

8.Output

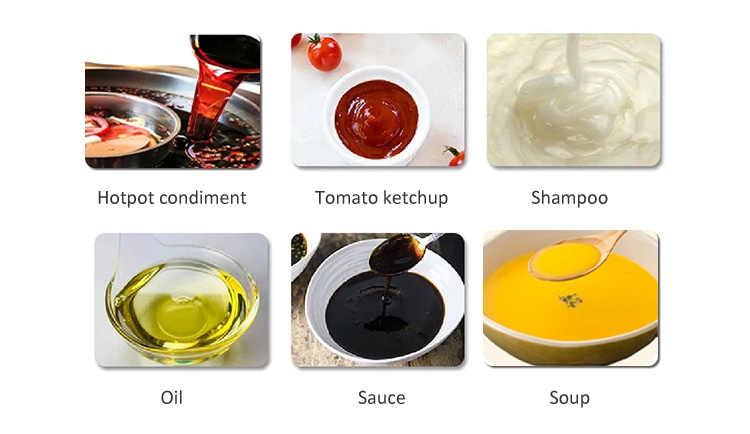

Packaged products are widely used

Meanwhile, the machine has been used in more than 40 countries and regions and is applicable to many fields such as solid, liquid, sauce and powder of nuts, snacks, condiments, spices, foods and detergents in agriculture, food, daily chemical and pharmaceutical industries.

Liquid:Such as juice, sauce, honey, jam, ketchup, oil, shampoo, shower gel, milk, soybean sauce, mayonnaise and so on

Bag type: Stand up pouch, flat pouch, pe pouch, gusset pouch, retort pouch, spout pouch

✔ With a device can against sealing vacant pouches to make sure that if there is no fill, there will be no seal.

✔ With a device can against sealing vacant pouches to make sure that if there is no fill, there will be no seal.

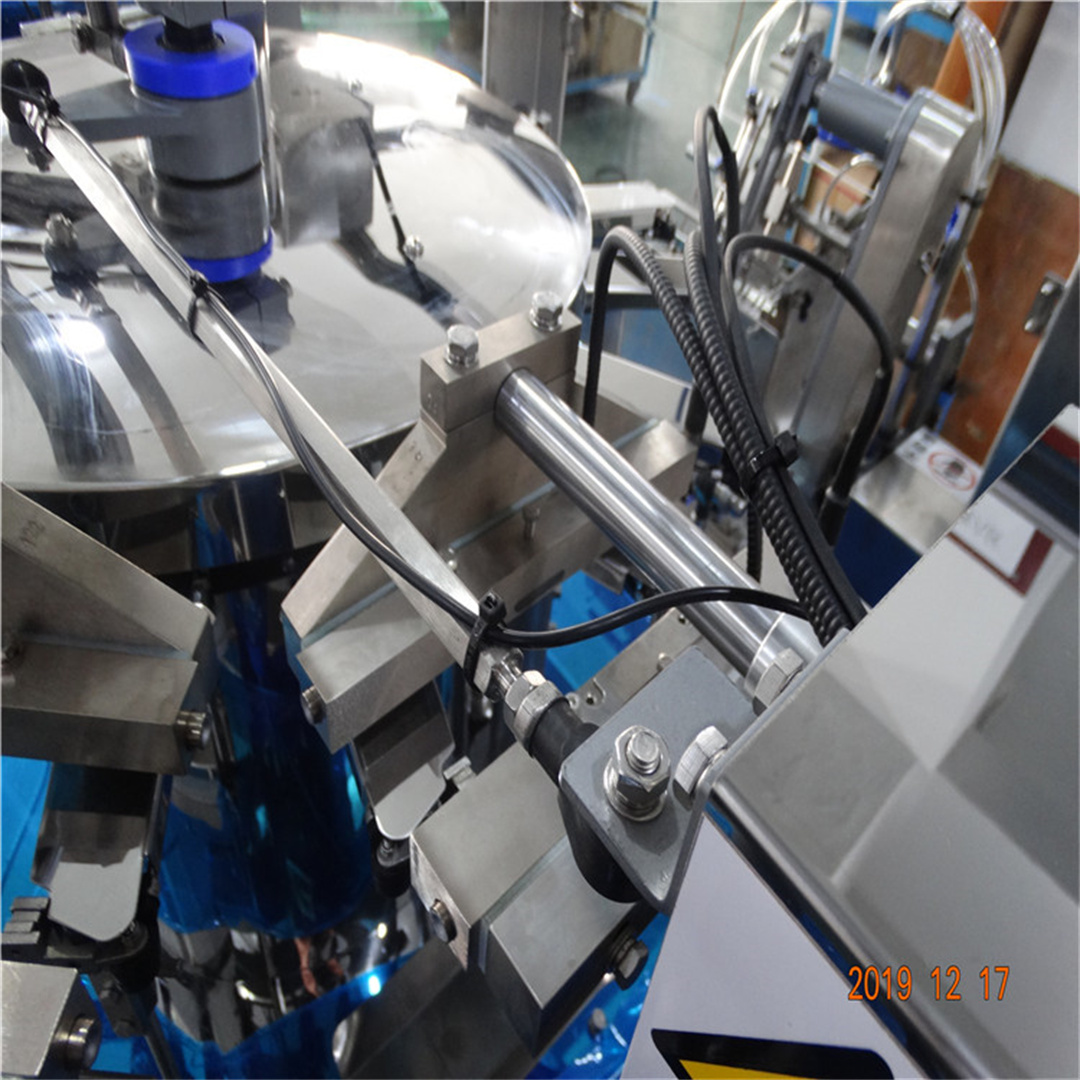

✔ Patented gripper system

✔ Maximum precision

✔ Flexible pouch type: stand-up pouches with zipper or corner spouts, quad pouches and pouches with customers’ design

✔ Flexible production speed 15-90 pouches/min.

✔ Long work time and lifetime can work 24 hours a day, only one day off for maintenance per month.

✔ Easy to operate and maintain, one person is enough.

✔ Easy conversion with different scales, fillers,pumps.

✔ High profitability can replace at least 7 workers for packaging.

✔ Low energy and maintenance costs, only a few spare parts need to change.

✔ Fast delivery of spare parts, for example, max 3 normal days to reach you

| Power supply | 380v 3phase 50Hz |

| Compressed air | about 5~8kgf/cm²,0.4m³/min |

| Drive method | Cam |

| Fill station | 2 |

| sealing style | straight/net type |

| Workstation | 8/10 station |

| Min bag width | 80mm |

| Max bag width | 305mm |

| Noise from running machine | within 75db |