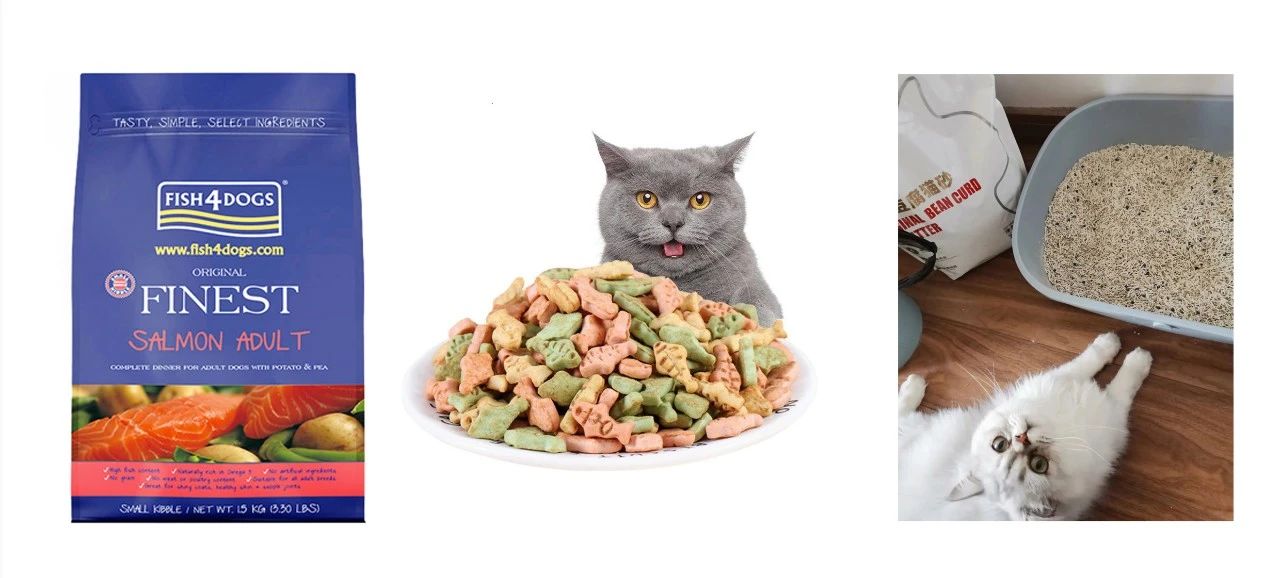

In recent years, the pet industry has ushered in explosive growth. With the improvement of people’s living standards, the status of pets in the family is becoming more and more important, and the pet economy continues to heat up. According to data from authoritative market research institutions, in the past five years, the global pet food market has steadily expanded at an annual rate of 8%, of which dry pet food, as the main category of pet food, occupies nearly 60% of the market share. In China, the dry pet food market is also growing rapidly, the number of pet families in first- and second-tier cities is rising, and the demand for high-quality and diversified pet dry food is becoming increasingly strong, which has brought huge development opportunities for pet dry food manufacturers.

However, while huge opportunities coexist, dry pet food manufacturers are also facing a series of challenges and problems that need to be solved urgently.

Low packaging efficiency: Traditional manual packaging or semi-automatic packaging methods rely on a large number of manpower to carry out operations such as bag picking, loading, and sealing, which is slow and difficult to meet the growing demand for market orders. During the peak season, manufacturers often miss business opportunities due to the inability to keep up with the packaging speed, resulting in delivery delays.

Poor measurement accuracy: Dry pet food particles are different in size and shape, and it is difficult for manual or simple metering equipment to ensure the accuracy of the weight of each bag. Weight deviation not only affects the reputation of the product, but also may face the risk of regulatory penalties and damage to the brand image.

Difficult to control packaging quality: manual operation is prone to problems such as loose sealing and broken bags, which leads to moisture, oxidation and deterioration of dry pet food, shortens the shelf life, and increases the cost of after-sales return and exchange.

Prominent health hazards: food packaging has extremely high requirements for hygiene, and in the process of manual packaging, personnel frequently contact with materials, which is easy to introduce bacteria and impurities, and does not meet strict food hygiene standards.

At present, in terms of automatic packaging in the domestic market, it is a traditional conventional bag packaging machine, with a packaging speed of 15-20 bags/min, and the stability is not good, the actual production yield is low, and the front-line personnel are difficult to operate.

In response to the above problems, Qingdao Yilong has provided strong support to customers with its self-developed high-speed dry food bag packaging machine, and the four advantages help dry food manufacturers overcome difficulties and achieve more efficient production.

1. High degree of automation: Yilong dry food bag packaging machine can automatically complete a series of packaging processes such as bag taking, bag opening, measurement and filling, sealing, output, etc., greatly reducing labor input, a production line only needs 1 operator to monitor and assist, reduce labor costs at the same time, improve the packaging efficiency to 30-40 bags / minute, especially suitable for large-scale batch production enterprises, can complete a large number of orders in a short time, and quickly occupy the market.

2. Accurate measurement: The equipment is equipped with advanced imported load cells, which can accurately control the filling amount according to the characteristics of pet dry food, and accurately control the error to ensure that the weight of each bag is consistent and meet the strict requirements of consumers for product weight.

3. Reliable packaging quality: Qingdao Yilong has been deeply involved in automatic packaging machinery for 28 years, and the equipment adopts advanced technologies such as full mechanical transmission, automatic refueling and lubrication, and is equipped with international first-line electrical brands, and runs smoothly. The packaging process is fully enclosed to reduce external pollution and meet food hygiene and safety standards. The bag is sealed smoothly and tightly, which effectively avoids the problem of broken bag and air leakage, and prolongs the shelf life of dry pet food.

4. Flexible adaptation to multiple specifications: The equipment can quickly change the mold and adjust the parameters with one click, and adapt to different sizes and shapes of packaging bags and various specifications of dry pet food, whether it is a small package of small dog food or a large package of large dog food, it can easily deal with it.

Qingdao Yilong has always been “to make trustworthy products, to do sincere and fast service” for the purpose, attaches great importance to product research and development quality and production control, built a comprehensive and mature management system covering from R & D design to after-sales service, and strives for the vigorous development of China’s pet food industry.

Post time: Mar-22-2025